- Contact Person : Ms. Guo Lisa

- Company Name : Shangqiu Haotian Environment Protection Machinery Equipments Co., Ltd.

- Tel : 86-370-2996888

- Fax : 86-370-2961569

- Address : Henan,Shangqiu,Shang qiu city 310 state road west kaixuan intersection 50 meters

- Country/Region : China

- Zip : 476000

Related Product Searches:Environmental friendly waste plastic pyrolysis machine with high oil rate,High Quality,waste plastic recycling plant, used plastic pyrolysis machine,HT-1

Waste or Treasure?

Waste tire, waste plastic, waste rubber, waste oil etc. are increasing every moment.

At the same time, oil resources are decreasing every single day.

How to deal with these problems?

We use green technology recycling waste to oil resources.

We are specialized in manufacturing pyrolysis machine for recycling waste tires, waste plastic, waste rubber etc. and distillation machiner for recycling waste oil, crude oil, black oil etc.

Technology advantages

The equipment has reasonable design and advanced manufacturing technologies and a high automation degree and complete safety facilities.

Advantages:

1.We are direct manufacturers and leaders in this field.

2.Our engineer has more than 30 years oil refining experience.

3.Through QC by every workers and engineers.

4.Product safety and pollution free .

5.The engineer always improve the machine according to the latest technology .

6.We have long-term cooperative forwarder who can provide cheap ocean freight for you.

7.We have ISO, CE and national patents.

7.1 Instead of landfill or burnng, this is a green technology for waste management

7.2 Pyrolysis machine - turn waste tire, waste plastic, waste rubber into fuel oil

7.3 Distillation machine - turn tire oil, plastic oil, rubber oil into gasoline and diesel

7.4 Distillation machine - turn waste engine oil, black oil, crude oil into gasoline and diesel

7.5 Waste tire recycling machine, waste tire refining oil plant

7.6 Waste plastic recycling machine, waste plastic refining oil plant

7.7 Waste oil recycling machine, waste oil refinery plant

Our certificates

The condenser

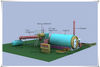

Systems of equipment

Reaction tank: waste oil will be pumped into this tank after pretreated.

Heating system: through burning coal or fuel oil to make the oil temperature up to setting value. this system equipped with insulation system.

Catalytic system: waste oil reaches the predetermined temperature, via catalytic effect, and then the gaseous hydrocarbons will become gasoline, kerosene and diesel composition.

Cooling system: gasoline, kerosene and diesel after catalytic effect can be condensed into liquid materials.

Temperature control system: ensure that waste oil transform into gasoline, kerosene and diesel oil, waste oil drying by distillation, can stop heating timely.

Exhaust gas handling system: a small amount of not liquefied gas via treated, can meet emission standards.

The reactor

Technical Parameters

Items | Contents | ||

Raw material | Waste tyres, scrap plastic, waste rubber | ||

Structure form | Horizontal | ||

Model | HT-1 | HT-5 | HT-6 |

Size of reactor | 2200mm*6600mm | 2800mm*6600mm | 2600mm*8800mm |

24-hour capacity | 5 tons | 10 tons | 15 tons |

Operating pressure | negative pressure | ||

| Power | 12--13KW | ||

Heating material | direct heating | ||

Average out-put oil rate | tyre:45% plastic:33%--85% | ||

Thickness of reactor | 14mm,16mm,18mm,20mm | ||

Rotate speed of reactor | 0.4 turn/minute | ||

Mode of cooling | Water cooling | ||

Working mode | Continuous feeding | ||

Delivery time | 20 days after receiving deposit | ||

Payment term | T/T, 30% in advance, balance paid before shipment | ||

The transportation

Safety:

1. Professional sealing technology for cover, oil outlet.

2. Heavy oil is separated which can avoid the problems of jam in later condensing.

3. Vacuum system will prevent exhaust gas from going back to reactor and causing accident.

4. Alarm, safety valves, thermometer, pressure gauge and safety valve.

5. It is dangerous to burning exhaust gas (C1 to C4). In our process, it is transferred first through the safety device and a safety burning air muzzle. Before burning, we should ensure the safety of production.

The end product

Environmental friendly waste plastic pyrolysis machine with high oil rate